Automation & System Integration

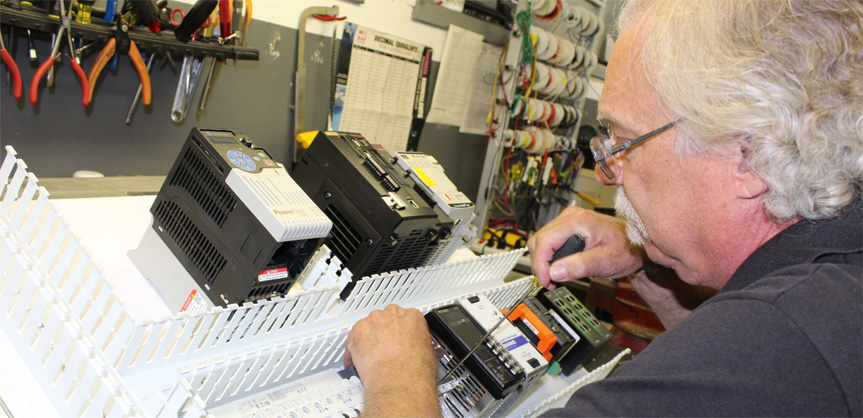

Tri-Power Design, LLC has provided automation systems integration for over twenty years. We help manufacturers achieve their automation goals through complete factory automation systems integration. Our services include system engineering, system consulting, PLC programming services, control programming, hardware upgrades, and complete turnkey automation solutions. We deliver professional support in demanding manufacturing environments. Tri-Power Design & Automation has completed projects in aerospace, automotive, food, consumer products, pharmaceuticals, utilities, material handling, manufacturing, and semiconductor industries, including contract manufacturing support for critical components.On every project, we meet and exceed customer goals with solutions that are creative, practical, cost-effective, and adaptable to daily operations. In addition, we deliver high-quality engineering expertise, service, and support on schedule. Our skills in design, fabrication, and integration allow us to provide end-to-end automation solutions that help you move faster. Our clients include FORTUNE 500 manufacturers such as GE, Stryker, BD, and Johnson & Johnson, as well as many other leading companies. Knowing they expect the best, shouldn’t you?

Tri-Power Design, LLC has provided automation systems integration for over twenty years. We help manufacturers achieve their automation goals through complete factory automation systems integration. Our services include system engineering, system consulting, PLC programming services, control programming, hardware upgrades, and complete turnkey automation solutions. We deliver professional support in demanding manufacturing environments. Tri-Power Design & Automation has completed projects in aerospace, automotive, food, consumer products, pharmaceuticals, utilities, material handling, manufacturing, and semiconductor industries, including contract manufacturing support for critical components.On every project, we meet and exceed customer goals with solutions that are creative, practical, cost-effective, and adaptable to daily operations. In addition, we deliver high-quality engineering expertise, service, and support on schedule. Our skills in design, fabrication, and integration allow us to provide end-to-end automation solutions that help you move faster. Our clients include FORTUNE 500 manufacturers such as GE, Stryker, BD, and Johnson & Johnson, as well as many other leading companies. Knowing they expect the best, shouldn’t you?Automation Systems Integration Experience

We’ve assembled a dynamic staff with experience in design, programming, project management, manufacturing, and quality assurance. As a result, our team approach identifies issues early and reduces costly changes later in the production cycle. We collaborate closely with clients to deliver reliable automation systems and controls.

Turnkey Systems

Tri-Power Design integrates standard machinery and custom-built equipment to deliver complete turnkey systems. This includes custom automation equipment, integrated industrial automation systems, and turnkey test equipment. In addition, our team supports clients as experienced automation machine builders. We can assume total project responsibility from concept through delivery, and we scale support to match your needs.Confidentiality

We understand confidentiality requirements and support projects involving proprietary concepts, technology, and processes. Therefore, customers in competitive markets rely on us to protect trade secrets. We apply strict confidentiality practices throughout development, integration, and support.Automation Capabilities

We design, modify, and build complete automation systems in the following areas:- Material Handling Systems

- Mechanical or Robotic Pick & Place

- Hi-Speed Inspection and Vision Systems

- Production Development and Test Equipment

- Assembly Line Systems with Hi-Speed Transfers

- Complete integration or retrofit into any major PLC

- Steel, Aluminum, and Ultrasonic Plastic Welding Stations...and many more automation-related projects