Manufacturing

In-House Manufacturing Services

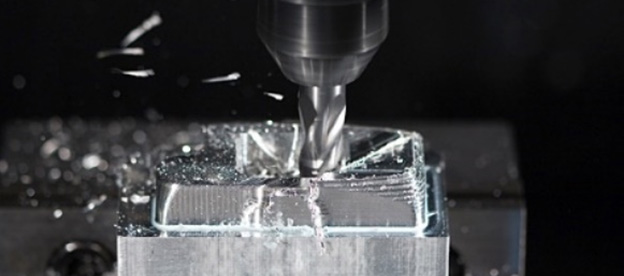

Over the past two decades, Tri-Power Design’s in-house manufacturing services have grown beyond what is typical for an engineering firm. Our advanced manufacturing facility supports everything from functional prototypes and aluminum prototype manufacturing to CNC machining, plastic fabrication, precision grinding, and full custom fabrication.

In addition, our strong focus on Design for Manufacturability (DFM) bridges the gap between engineering services and production. This approach ensures cost-effective output and consistent quality. Quality control remains central to every project and follows ISO 13485 standards. Because we maintain vertical integration, we deliver reliably by keeping key processes—from heat treating to assembly and testing—within our Denville, New Jersey facility.

Manufacturing Capabilities and Fabrication

Tri-Power Design is ideally positioned to support clients with the following production capabilities. For related automation work, see our automation systems integration services.

- Contract Manufacturing – Whether you outsource all or part of your build, Tri-Power Design provides flexible support for aerospace, consumer product, and automation equipment programs, with expertise in the following areas:

- Low-Volume Manufacturing – From single parts to hundreds of assemblies, our low-volume CNC machining and short-run builds deliver speed and precision.

- Validation and Lab Instruments – We produce components that meet strict requirements, including medical device parts and validation instruments built to ISO standards.

- One-Off Parts – We produce one-of-a-kind prototype parts using advanced machining technology, including 5-axis CNC Haas machining and innovative fabrication techniques.

- Machine Fabrication – We provide full machine fabrication services, including steel and aluminum structures and custom welding. These services support our automation team or meet standalone client specifications.

| Manufacturing Equipment | Inspection Equipment |

|

|

Call 973-227-8214 or email us today so we can help you with your manufacturing needs.